Project Detail

Halhal Small-Scale Earth Dam Construction (Dam Mikilim)

In 1997, the Ministry of Agriculture (MOA) initiated the construction of a small-scale earth dam in Halhal village, located in the Anseba region of Eritrea. The primary objective of the dam was to conserve water for irrigation, ensuring a sustainable water supply for agricultural purposes. This enabled the village farm to benefit directly from the reservoir water or indirectly through replenishing the groundwater system.

Period of Construction

The dam was constructed over approximately four months, from February 1997 to June 1997, requiring intense and focused efforts to complete the project within the planned timeframe.

Location

The dam is situated in Halhal village, within Eritrea’s Anseba region. Figure 1 provides a bird’s-eye view of the completed reservoir, highlighting its strategic importance to the surrounding agricultural activities.

Figure 1 Halhal small-scale earthdam, Mikilim Dam (google image)

Enterprise

The Ministry of Agriculture (MOA), based in Asmara, the capital of Eritrea, spearheaded the project. This governmental organization operated through six regional offices and numerous sub-regional offices, with its principal office strategically located in Asmara to oversee agricultural initiatives across the country.

Method of Construction

The construction of the dam involved the extensive use of heavy machinery, including:

- Rollers, loaders, bulldozers, and graders for earthworks.

- Loading trucks and pickup vehicles for transportation and logistical support.

This mechanized approach ensured efficient progress, enabling the timely completion of the project.

Responsibilities

In addition to constructing the dam, the team was tasked with monitoring and implementing other small-scale diversion structures in nearby areas. One notable project was in the Asmat area, where a small weir structure was built to redirect flash floods into a basin irrigation system, improving water distribution and agricultural productivity.

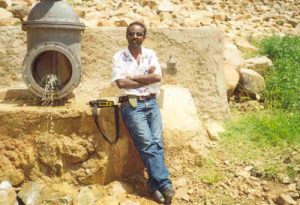

Figure 2 illustrates the survey conducted for the Asmat irrigation project, showcasing its integration into the region’s broader water management strategy.

Figure 2 Photo taken at Asmat irrigation project, 1997.

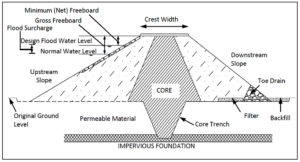

Figure 3 Typical example of earth dam profile.

Figure 4 Gravel filter lying, Halhal.

Spillway

The spillway was a simple excavated channel with a width of approximately 10 meters and a depth of about 1.5 meters. Its length extended downstream, connecting to the natural course of the existing river, as shown in Figure 1.

The freeboard level of the dam was set at 15.5 meters above the base, meaning the maximum water depth in the reservoir could reach 15.5 meters. The reservoir’s fetch length extended over 120 meters towards the upstream boundary, ensuring sufficient water storage capacity.

Outlet Structure

The outlet consisted of a standard concrete pipe, protected by a reinforced concrete cover for durability and safety. To minimize seepage (creeping water) along the pipeline, 11 collars were installed at intervals of 7 meters along the pipe.

Figure 5 illustrates the type of collars used at the Halhal Dam. Although the image is sourced from the internet, it provides a clear representation of the design and purpose of the collars implemented in the project.

Figure 5 Seepage protection collar.

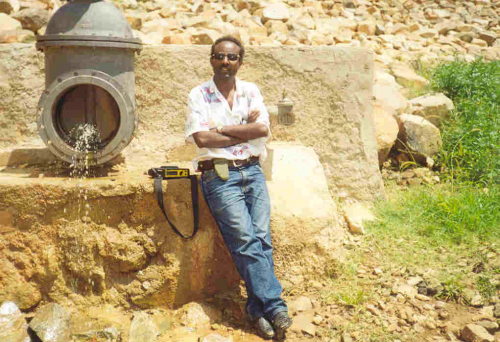

The outlet structure at Halhal shown in Figures 6 and 7

Figure 6 Halhal outlet structure (photo taken after the construction ended).

Figure 7 Valve and concrete pipe connector used at Halhal dam.

Foundation

The foundation along the central axis of the dam was excavated and filled with compacted clay soil, extending up to the freeboard level. Figure 8 illustrates the construction process of the Halhal Dam.

Figure 8 Construction of Halhal Earth Dam (Dam Mikilim).

Compaction

The compaction process was carried out using two rollers. The methodology involved rolling back and forth four times over a 0.3-meter-thick layer of soil while simultaneously applying water to aid in compaction. A bulldozer was used to evenly spread the soil across the surface before the rollers compressed it.

Figure 9 illustrates the compaction process at the Halhal Dam construction site.

Figure 9 Compaction of Halhal dam

Hydrological Studies

The hydrological study for the Halhal Dam was conducted using empirical formulas. It was estimated that 10% of the annual rainfall contributed to runoff. The total runoff volume was calculated by multiplying the runoff depth by the catchment area (watershed). This approach provided a straightforward estimation of the potential water availability for the reservoir.

Project Cost

As a government project, the exact cost of the construction could be retrieved from the relevant government bureau. However, a rough estimation can be made based on the machinery used and the personnel involved during the construction period.

Machinery Utilized (8 hours/day during weekdays):

- Two compactors

- A loader

- An excavator

- Two bulldozers

- A grader

- Water tank trucks

- Two pickup vehicles

- Two loading trucks

Personnel Involved:

- One trained engineer

- A foreman

- Two machinery foremen

- Operators for each machine

- Approximately 20 laborers and craftsmen

The total cost, excluding materials such as fuel, cement, sand, reinforcement bars, concrete pipes, and vehicle repairs, was estimated to exceed 1 million Nakfa (approximately $71,428.57). This estimate is based on the monthly earnings of the personnel involved in the project.

Role of the Site Engineers

The site engineers were instrumental in ensuring the quality and success of the project. Their key responsibilities included:

- Regulating the concrete mix and soil types.

- Assisting foremen with interpreting drawings.

- Monitoring and controlling the compaction process.

- Organizing machinery and construction materials.

- Managing the reinforcement bar schedule.

- Translating design plans from paper to the site.

- Guiding excavation work.

- Supervising the overall construction process according to the project plan.

The construction team comprised skilled and unskilled personnel, including engineers, carpenters, masons, and laborers. A significant number of machinery operators and foremen were also involved in ensuring the project’s smooth execution.

Points to Highlight

- Location: Halhal, Anseba Region, Eritrea

- Type: Earth dam

- Height: ~17 m

- Crest Width: ~5 m

- Crest Length: ~65 m

- Spillway (Earth) Width: 10 m

- Dam Profile Slope:

- Upstream (U/S): 1:3

- Downstream (D/S): 1:2

This combination of practical expertise, resource management, and efficient engineering design contributed to the successful completion of the Halhal Dam, serving as a vital water conservation infrastructure for the region.

Link to the current status of the dam

[put_wpgm id=3]