Project Detail

Assab Regional Hospital Construction

Due to the lack of adequate healthcare facilities in the Assab region, the Southern Red Sea Regional Eritrean Defense Force (EDF) initiated the construction of a referral hospital in January 2000. This facility was designed to meet the healthcare needs of the region and was strategically located on the outskirts of Assab city.

Enterprise

Executing Body: Southern Red Sea Eritrean Defense Force (EDF) Construction Department, Assab, Eritrea

Construction Period

The project spanned from June 2000 to early 2006, involving extensive planning and execution over six years.

Description of the Facility

The hospital construction featured a ground plus one complex, including:

- Outpatient Building (OPD)

- A 200-bed healthcare facility center

In addition to the main hospital building, several auxiliary service buildings were constructed to support operations.

The healthcare facility provides services across multiple sectors, including:

- Obstetrics and Gynecology

- Orthopedics

- Surgical Theater

- Internal Medicine

- Dentistry/Odontology

- Pediatrics

Based on design documents, the construction site covers an approximate surface area of 124 square meters.

Overview

Figure 1 presents a bird’s-eye view of the Assab Regional Hospital, highlighting the facility’s layout and surrounding infrastructure.

This project marked a significant step in improving healthcare accessibility in the Southern Red Sea region, equipping the area with modern medical facilities and specialized healthcare services.

Figure 1 Building complex of Assab referral hospital.

Foundation Considerations

The Assab region, being a wasteland situated along the Red Sea, posed significant challenges due to the high salt content in the soil. This salinity had the potential to degrade construction materials over time, causing structural failure.

To address this, all footings were constructed using sulphate-resistant cement (SRC). This type of cement was specifically chosen for its ability to withstand harsh environmental conditions, including high levels of sulfates, chlorides, and saltwater.

The Effects of Salinity

In Assab, it is common to observe buildings damaged by salt infiltration. Salt moves upward through capillaries in the soil, attacking wall surfaces and columns. Over time, this leads to corrosion of reinforcement bars, reducing their load-bearing capacity and causing premature structural failure. The use of sulphate-resistant cement was, therefore, an indispensable measure to ensure the durability and stability of the foundation.

Benefits of Sulphate-Resistant Cement:

- Minimizes heat generation during curing.

- Provides high resistance to sulfates, chlorides, and saltwater.

Construction Process

Layout

The construction layout began with transferring the key points of the design to the ground using surveying instruments such as theodolites and leveling tools. Batter boards and construction lines were then set up to guide the excavation process.

Excavation

The excavation, or removal of soil from the foundation area, was carried out using mechanical excavators to achieve precision and efficiency.

Lean Concreting

Before placing the foundation formwork, a 5 cm-thick layer of lean concrete was cast to create a level and stable base. This step provided additional support and protection for the foundation structure.

Figure 2 illustrates the lean concreting process at the Assab hospital construction site.

These measures were vital to overcoming the challenges presented by the saline environment, ensuring the long-term stability and safety of the hospital’s foundation.

Figure 2 Lean concreting at Assab construction site

Foundation Placement

Due to the site’s rocky and robust geological formation, the required excavation depth was relatively shallow, ranging between 1.5 to 2 meters. This minimized the need for extensive excavation, reducing construction complexity and cost.

The type of foundation employed was a spread footing foundation, with each footing measuring approximately 120 cm x 85 cm and a depth of 45 cm. This design provided adequate support for the structure, ensuring stability and durability.

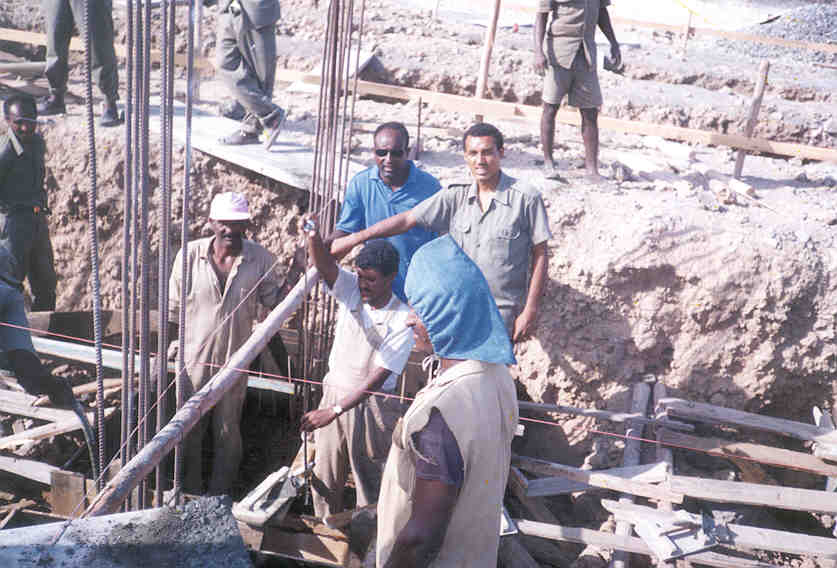

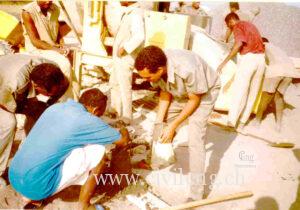

The girder beams and all columns were cast in situ, a method that enhanced the structural integrity by creating a seamless connection between the components.

Figures 3a, 3b, and 3c illustrate the placement of the foundation and columns at the Assab hospital construction site, showcasing the meticulous attention to detail in the process.

Figure 3a Constructing the foundation and columns of Assab Referral Hospital.

Figure 3b Single spread foot foundation utilized at Assab Hospital.

Figure 3c Foundation formwork placement.

Figure 3c Foundation formwork placement.

Concrete Mixing Ratio

The standard mortar mix used was B25, applied uniformly for the foundation, beams, and columns. The mix ratio consisted of cement: sand: gravel in the proportion of 1:2:4.

Figure 4 displays the concrete mixing machinery utilized at the Assab Hospital construction site, which ensured consistency and quality in the preparation of the concrete.

Figure 4 Mobile concrete mixer utilized at Assab Hospital

Slump Test

The construction adhered to standard concrete mixing procedures, and the consistency of the concrete mix was evaluated using the slump test technique, a straightforward and effective method.

Assessing the concrete mix consistency is crucial, as it prevents the adverse effects of excess water in the mortar or concrete. Excessive water can compromise the structure by leaving cracks as the water evaporates. Over time, these cracks can lead to the corrosion of reinforcement bars, ultimately resulting in premature structural failure.

Validating the consistency of the concrete mix ensures the durability and integrity of the structure, helping to avoid such issues.

Figure 5 illustrates the slump test procedure carried out during the construction process.

Figure 5 Slump test

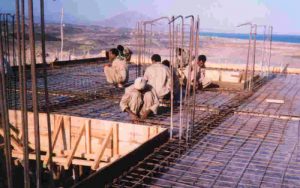

Figures 6a and 6b depict the structural framework of the OPD (Outpatient Department).

Figure 6a Outpatient department construction in progress

Figure 6b First-floor reinforcement placement

Figure 7 Assab referral hospital completed OPD building

Responsibilities of the Engineers

The engineers played a pivotal role in ensuring the project’s success. Their primary responsibilities included:

- Regulating the concrete mix to meet quality standards.

- Assisting foremen in interpreting and executing design drawings.

- Guiding the cutting, bending, and positioning of reinforcement bars (bar scheduling).

- Translating the design from paper to the construction site, ensuring alignment with the project plan.

- Supervising the excavation process and providing direction during construction.

- Overseeing the overall construction activities to ensure adherence to the project specifications.

Equipment and Personnel

The construction utilized various pieces of machinery, including:

- Movable and stationary concrete mixing machines

- Vibrators for concrete compaction

- Vehicles and trucks for material transport

Skilled and Non-Skilled Workforce

The workforce consisted of:

- Two trained engineers

- A co-engineer/aide engineer

- A technician

- A carpenter foreman

- A mason foreman

- Several carpenters and masons

- Hundreds of non-skilled laborers regularly sourced from another infantry brigade

Most of the participants were military personnel offering their services as part of their duties. However, four permanent members of the military (referred to as patrons) were specifically employed and paid by the construction department of the defense force.

Cost of the Project

Estimating the cost of the project is challenging due to the lack of original plans and material records. However, an approximation can be made based on the human resources and materials utilized. The detailed estimation would include:

- Salaries for the skilled and non-skilled labor force

- Machinery operation costs

- Material costs, including cement, reinforcement bars, and transport

Key Points

- Location: Assab Sekir, Eritrea

- Construction Surface Area: Approximately 124 m²

- Type: Ground plus one building complex (OPD and a 200-bed health facility center)

This project demonstrated meticulous planning, resource management, and effective engineering oversight, contributing to a critical healthcare infrastructure for the region.

[put_wpgm id=4]